Recently I had a chance to spend some time talking to Dan Rice of Bozeman Reel. If you haven’t heard of Bozeman Reel, you’re missing out. These reels are made right in Bozeman, Trout Town USA. “Built Montana Tough” is one of their slogans. Playing around with their reels, you can see they live up to their name. It’s a crowded market out there, but every now and then you run into one of those products and companies that stands out from the crowd. Bozeman Reel is one of those companies.

Check out their website here at BozemanReel.com, and you can also check them out on Instagram, Twitter, and Facebook.

All photos by Shane Rickert.

How did the company get started? I think a lot of folks would wonder just why in the hell you would want to start building high end fly reels in a crowded market.

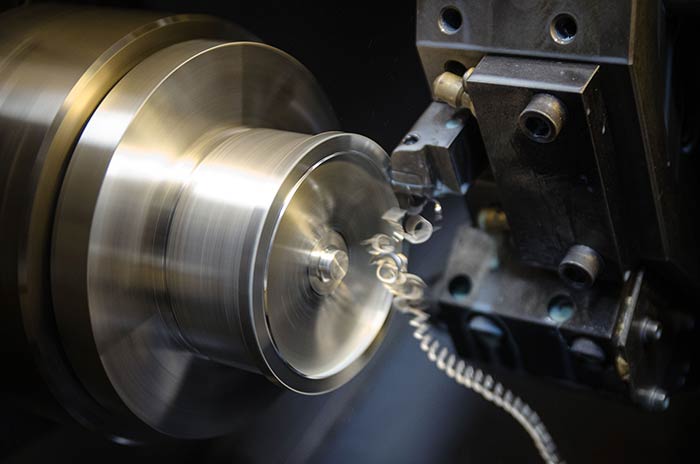

It was a small group of Montana State University alums that were fisherman, engineers and machinists. The idea was born out of the reality that there wasn’t a reel company in Montana nor one that focused on producing a mix of modern technology and classic styling. The shop here builds all sorts of products and this was a way to differentiate the business and help us grow our own product offering.

Why Bozeman? I’m sure there’s a lot of places you could have based the company from.

Why anywhere else? The capabilities that we have here in town are second to none and the team that we have focused on design, machining and assembly are die-hard fly fisherman and women who are passionate about building our brand.

You mentioned the cost of a factory tour is a six pack of beer with no quality requirement… What’s the favored beer around the shop?

Montucky Cold Snacks, Bozone Amber or PBR (Tall boys). We had one crew of my friends come in and deliver those white cans that said “Beer” on the side. No one complained. We’re just psyched to fill the fridge! The machinists love having people through the shop now… they know that there is a prize coming. It hasn’t affected quality (we don’t start drinking until the work ends), but it definitely has improved employee morale!

Talk to me about the concept of “Negative Space”.

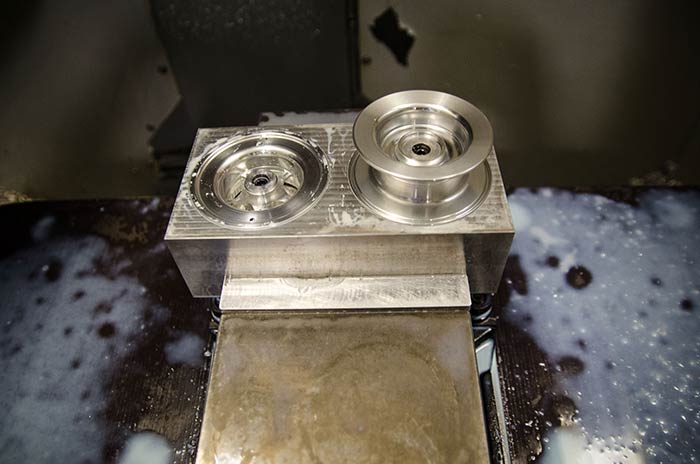

When you start with the material to make a machined fly reel, there is a tremendous amount of Negative Space that needs to be carved away. This process reveals the structure of a Bozeman Reel. Following that process through our production facility you see how involved the process is and you see all of that aluminum being carved from the starting block. In our reels, its over 2 lbs of material carved away to showcase a ~5-7 oz reel.

This process via aluminum is similar to the feelings that I think we all experience when we escape to a river. The shedding of stress, of everyday expenditures to end up in the solitude and relaxation of being on a river.

We could make reels that weren’t as technically challenging… and you could fish with bait. But that isn’t what this is about. It’s about producing a quality product (a reel or a fly) to a quality consumer (the fisherman or the fish) and having them satisfied… only, in that analogy, the fish may be a little unhappy in the end!

You mentioned that your reels are crafted using recycled materials? Why go that route?

Correction – our reels don’t use recycled materials. We use top-notch materials in the construction of our reels themselves. We DO recycle all of the waste material that is leftover from production – so the cycle does wrap a bit there.

We do use recycled materials in the packaging and collateral. We use some recycled material in our reel cases. We work to use scraps where possible in the production of our boxes.

I wouldn’t necessarily call it recycling, though… its that new term… upcycling. We’re taking something that is scrap to someone else and turning it into a functional and stylish accent to your reel. It isn’t less expensive to do that, but in our little way it is better.

Check back tomorrow for Part 2 of the interview.