If you missed the first part of the conversation with Dan Rice of Bozeman Reel, you can find it here.

You’re obviously trying to create something more than just a reel company with this. It seems that culture and community are pretty important. What are your goals in that area?

We want to have fun and create a brand that people can rally around. We don’t want BRC to be just a brand, though. The reels are the forefront of what we do and the focus of our business right now. But, I believe that there is room for enhancement in this area. Yes, the reel market is a crowded space, but if we do what we seek – develop a quality reel that resonates with people, then we’ve started in the right direction. That affords us the opportunity to then innovate on design, expand the product catagories and carry the same enthusiasm into other areas of fly fishing. We’ve got a ton of ideas here that could turn into something, but we need to “prove” ourselves in this market by producing quality reels that get people really pumped about BRC.

What is it that really makes Bozeman Reel different, to stand out in a crowd?

There are some design aspects of the reel that help to identify us with the premium market. We’ve spent a fair amount of time optimizing the drag for the supple start-up that is required to protect light tippets. We have a developed a reel testing unit that allows us to experiment with various drag systems and types which helped us settle on the drag system we use now – sandwiched rulon with just under 2 square inches of drag surface. This allows us to achieve sufficient stopping power, a one-turn on/off drag and a very light start-up inertia which will protect light tippets, when needed. Another aspect of our design that helps to differentiate is the way our spool is mounted on the housing. The spool is referenced against the conical spindle – in the same way that the high-tech CNC machines mount their cutting tools. It’s proven and it works.

The reels have a really great look to them… What has influenced their design?

The SC series is obvious… we just love some of the classic click/pawl designs and wanted to develop a line of our own. The RS series design had a lot of time spent on it. The simplicity and design differentiators were focused on weight reduction and aesthetics. I don’t know what really drove that, but we love it. Next up – spinners on that bad boy that really go nuts when you hook into a monster fish!

The M1 design is one of our hottest designs. Its not available right now, but we’re planning to bring it back. I adore those lines and the skeleton appeal to it. Is it classic, modern or a mix? I’m not sure.

So everything is done right there in Bozeman. Could you walk us through the process of taking a chunk of aluminum and turning it into a fine fishing instrument?

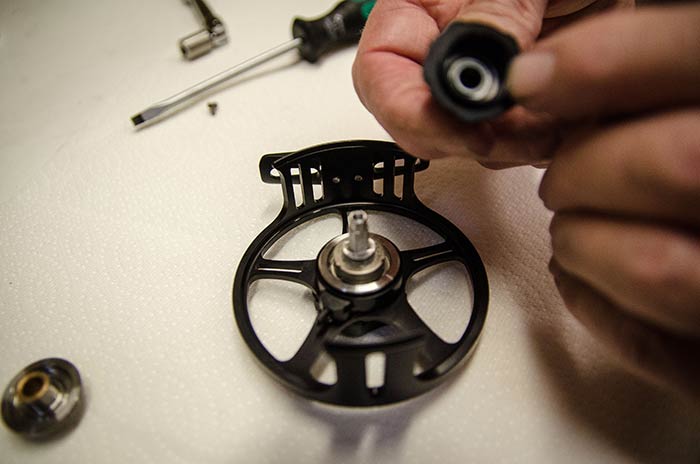

It’s a pretty amazing process. Bar stock aluminum is cut into pucks or billets. Those pieces are put into the lathe to do the turning operations. From there the parts are moved to the mill where the multiple axis mill operations are performed. These machines carve out the spaces of the reel that really accent the design. This work is done with more precision than that of a surgeon’s knife. We then tumble and finish the aluminum before anodizing.

The anodizing process is fascinating… You literally build a barrier on the metal. It can be worked off over time, but is tremendously tough and will provide the longevity to our reels.

Following anodizing, we do the final process steps (laser engraving, finishing coloring, etc.) and then head over to assembly. These are assembled by hand, inspected and boxed up ready for the shop or the consumer.

We are including some “freebies” with our reels, too. We’re starting a Bozeman passport of sorts and including free drinks at Bozeman Spirits, beer at Bridger Brewing, coffee from Nova Café, chicken from Roost, pizza from Red Tractor… We want to introduce our customer to the other craft products in Bozeman.

What can we expect from Bozeman Reel in the future?

Great question… We’ve got a lot of ideas and are aligning our ability to produce quality products with our ability to innovate. We’d like to introduce some variations on the reels and expand our line there, but we also realize there are innovation opportunities outside of reels. How about this, you guys will be one of the first to know once we start releasing? (Dan, you’ve got a deal on that! -Jake)

Thanks Dan and the crew at Bozeman Reel for taking the time to answer my questions. We here at Chi Wulff are excited to see what is in store for the company.

Hat tip to Shane Rickert for the images in this interview.